Category

Contact

Tel: ( 86) 755-26996606

Fax: ( 86) 755-26007653

E-mail: rosemary@ussharp.com

Woods-tiger@ussharp.com

Web site: www.ussharp.com

Address: Floor 4, Jinhui Building, Nanhai Road, Nanshan District, ShenZhen

Product

Product details

Generall Description of End Mills:

end mills (also called Milling cutter) are cutting tools typically used in milling machines or machining centres to perform milling operations.Applications cover a wide range of industries such as Aerospace, Transportation, Medical Equipment, Military Manufacturing, Mold Development, etc. They remove material by their movement within the machine that differ from turning operations while cutters are fixed, material removed by the movement of workpieces in maching manufacturing industry.

Features of solid carbide end mills:

Generally, end mills has following features:

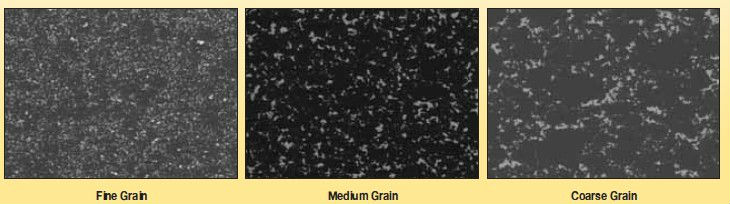

1,Raw Material: end mills are made from metal powders, the smallest powder provide highest quality of a mill.

2, Shape: this determine what kind of operation you are going to process. roughing or finishing, grooving or sloting, side milling or step milling, face milling or profiling .

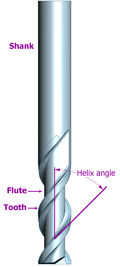

3,Flutes and teeth: Milling cutters may have from one to many teeth, with 2, 3 and 4 being most common. Typically, the more teeth a cutter has, the more rapidly it can remove material.

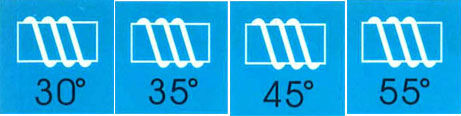

4,Helix angle: helix angle allows the tooth to enter the material gradually, reducing vibration. Typically, the larger helix angle, a better finishing surface after processing.

5,Coating: Coating increases cutting speed and tool life, and improve the surface finish.

6,Shank: shank is used to hold and locate it in the tool holder. The diameter may be different from the diameter of the cutting part of the tool, so that it can be held by a standard tool holder.

How to Select End Mills

Essentially we are all trying to choose a cutter which will cut the material to the required specification for the least cost.

thus,before selecting, we need to know well that what kind of operation we are going to have on the material.

1,Raw Material: Carbide last longer than Cobalt steel and high speed steel,

0.2µM Carbide powder are better than that of 0.4µM -0.5µM.

2,Diameter: cutting diameter, shank diameter, overall length etc

3, flutes:More flutes allows a higher feed rate.

4,Helix angle: low helix angles for hard or tough workpieces and High helix angles are typically good for soft metals

5,Coating: Coating reduce wear and increase tool life.

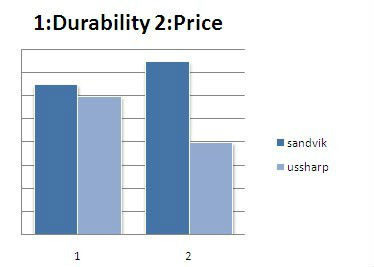

Comparing to Other Brands, Our Stength: